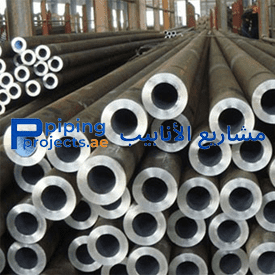

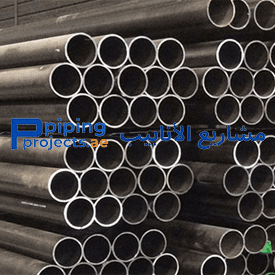

Piping Projects Middle East is a leading Alloy Steel Boiler Tube Manufacturer in Middle East. Various factors contribute to the creation of alloy steel for boiler pipes, making it both ductile and malleable. This type of steel exhibits remarkable mechanical properties. Another alloy steel commonly used for boiler tubes includes significant chemical components. These components, such as Ni, Cr, Mo, Si, and B, are frequently utilized to manufacturer seamless Low Alloy Steel boiler tubes. We are the top Alloy Steel Boiler Tube Supplier in Middle East.

Piping Projects Middle East is an esteemed Alloy Steel Boiler Tube Manufacturer, is dedicated to providing with reliable, top-notch Alloy Steel Boiler Tube. Here are the specifications for Alloy Steel Boiler Tube.

| ASTM Specification | ASME SA 213 / ASTM A213 |

| Standard | ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| ASME SA213 Chrome Moly Boiler Tube Size | 4 to 219mm W. T.: 0.5 to 20mm |

| Chromoly Boiler Tubing Size | 5.0 - 1219.2 mm |

| Alloy Steel EFW Boiler Tube size | 5.0 - 1219.2 mm |

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish, etc |

| Form | A213 Chrome Moly Boiler Tubing are available in form of Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Boiler Tubes, “U” Shape, Pan Cake Coils etc. |

| Grade | |

| Alloy Steel Boiler Tube | T9, T11, T22, T91, T92 |

Leading Alloy Steel Boiler Tube Manufacturer in Middle East - Piping Projects Middle East

Piping Projects Middle East is a well-known Alloy Steel Boiler Tube Supplier in Middle East. We supply Alloy Steel Boiler Tube to many cities and regions, including Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al Quwain, and Fujairah. We are trusted supplier in the UAE and other countries nearby. Our Alloy Steel Boiler Tube are excellent, and we are the preferred option for businesses and industries seeking high-quality piping solutions in the Middle East. We stand for on-time deliveries as we are the top Alloy Steel Boiler Tube Manufacturers in Middle East.

Alloy Steel tubes heat liquids and create steam in various operations. They are strong and can withstand high levels of tension and temperature, making them perfect for use with stainless-steel boilers. The fluid is heated by circulating within the tubes. These tubes can be made as soldered or continuous pieces. They are created by heating steel preforms and shaping them through a metallic die to manufacture Alloy Steel Boiler Tubes. We stand for on-time deliveries as we are the top Alloy Steel Boiler Tube Manufacturer in Middle East. We are also a leading Metallic Gasket Manufacturer in Middle East.

Piping Projects Middle East is a leading Alloy Steel Boiler Tube Supplier in Middle East. Our products come in different sizes to serve other uses and needs.

What are the Types of Chromoly Boiler Tubes?

Different Chrome Moly Water Tube Boiler shapes include circular, rectangular, hollowed, cylindrical, hydraulic, looped, linear, "U"-shaped, and pancake coiled. The ASTM A213 Alloy Steel Boiler Tubing contains 1.9% chromium and silicon, nickel, carbon, manganese, phosphorus, and sulphur. This Boiler Tube has a minimum yield point of 205MPa, a minimal compressive stress of 415MPa, and a maximum Brinell hardness of 163HB. These water tube boilers are used in harsh settings due to their strong resistance. The dimensional accuracy of the Alloy Steel Boiler Fin Tube is maintained. We are also a top-notch Alloy Steel Boiler Tube Manufacturer in UAE.

Alloy Steel Boiler Tube

Trusted

Supplier

Genuine

Product

Easy

purchase

What is the Working Principle of Alloy Steel Water-tube Boilers?

The Alloy Steel Water-tube boiler uses heat siphoning to move fresh water. It consists of a steaming and a lower drum, also called a mud drum.

Two pipes connect the drums, one acting as an outlet pipe and the other as a riser. At first, a water pump supplies water to the steam-type drum. When fuel is used, hot air enters the boiler's shell, resulting in its manufacturing. The hot air from the fuel causes the liquid to cool down, transforming it into vapour. As the water temperature increases, the concentration also increases significantly. We are also a leading Alloy Steel Boiler Tube Manufacturer in Middle East.

Alloy Steel Boiler Tube Weight Chart

| Grade | Outer Diameter (mm) | Wall Thickness (mm) | Weight (kg/m) | Weight (lb/ft) |

|---|---|---|---|---|

| A213 T2 | 19.05 | 2.11 | 1.48 | 0.997 |

| A213 T5 | 25.4 | 2.77 | 2.51 | 1.688 |

| A213 T9 | 31.75 | 3.38 | 3.45 | 2.319 |

| A213 T11 | 38.1 | 3.56 | 4.34 | 2.918 |

| A213 T22 | 50.8 | 4.06 | 6.04 | 4.058 |

| A213 T91 | 63.5 | 4.78 | 8.69 | 5.844 |

| A335 P5 | 19.05 | 2.11 | 1.48 | 0.997 |

| A335 P9 | 25.4 | 2.77 | 2.51 | 1.688 |

| A335 P11 | 31.75 | 3.38 | 3.45 | 2.319 |

| A335 P22 | 38.1 | 3.56 | 4.34 | 2.918 |

| A335 P91 | 50.8 | 4.06 | 6.04 | 4.058 |

What is the Use of Stainless-steel Boiler Vent Pipe?

The stainless-steel boiler vent pipe is an important part that helps remove leftover gases from the workplace. This helps improve airflow and oxygen levels in the unit. Using this pipe also reduces carbon monoxide levels in the area. These pipes can last at least 20 years and require little maintenance. The stainless-steel boiler flue pipe is used to transport gases and dangerous materials burned in the boiler outside the building and release them into the environment. We are also a leading Alloy Steel Boiler Tube Supplier in Middle East.

What is the Inspection Method for Low Alloy Steel Seamless Boiler Tubes?

PAUT and TOFD are the most effective methods for inspecting boiler tubes. It supplies technicians and examiners with comprehensive coverage and reliable processes. PAUT efficiently pulses beams in various directions to create cross-sections, even on rough surfaces and weld caps. TOFD uses longitudinal waves to monitor welds on both sides.

Alloy Steel Boiler Tube Size Chart

| Nominal Pipe Size (NPS) | Outside Diameter (OD) in mm | Wall Thickness (WT) in mm |

|---|---|---|

| 1/2 | 21.3 | 2.77 |

| 3/4 | 26.7 | 2.87 |

| 1 | 33.4 | 3.38 |

| 1 1/4 | 42.2 | 3.56 |

| 1 1/2 | 48.3 | 3.68 |

| 2 | 60.3 | 3.91 |

| 2 1/2 | 73.0 | 5.16 |

| 3 | 88.9 | 5.49 |

| 3 1/2 | 101.6 | 5.74 |

| 4 | 114.3 | 6.02 |

Where are Alloy Steel Fire-tube Boilers Used

Fire-tube boilers made of alloy steel are commonly used in small power systems and heating structures. They are also utilized in steam-powered operations. The advantage of these boilers is their easy installation and use. They are particularly suitable for smaller businesses and are also used by railroads. Additionally, they are employed in small hydroelectric power stations and ships. Seamless alloy steel boiler tubes are technical tools used to generate steam. These boilers find applications in various domestic and commercial settings. Different designs of boilers are available to meet specific application requirements.

Application & Uses of Alloy Steel Boiler Tube:

Piping Projects Middle East is a leading Alloy Steel Boiler Tube Manufacturer in UAE. We proudly supply high-quality Alloy Steel Boiler Tube to major Middle East Countries. We have dominated the market as the Middle East’s leading Alloy Steel Boiler Tube Exporter for a long time.

| Countries We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Saudi Arabia | Israel | Iran | Kuwait | Iraq | |||||

| Oman | Palestine | Egypt | Lebanon | Turkey | |||||

Alloy Steel Boiler Tube Manufacturer & Supplier

Alloy Steel Boiler Tube Manufacturer in Middle East

Alloy Steel Boiler Tube Supplier in Middle East