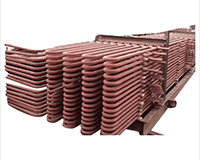

Piping Projects Middle East is a leading Boiler Tube Manufacturer in UAE. Boiler bank tubes carry both steam and liquid. Boiler Tubes of different sizes and shapes are bent to larger radii to prevent damage. This extends the boiler's lifespan and manufactures it more efficient and convenient. We are the top Boiler Tube Supplier in Middle East.

Piping Projects Middle East is an esteemed Boiler Tube Manufacturer, is dedicated to providing with reliable, top-notch Boiler Tube. Here are the specifications for Boiler Tube.

| Details | Specification | |

|---|---|---|

| Tube Size (OD and WT) | e.g., 2 inches OD x 0.25 inches WT | |

| Length | e.g., 20 feet or as per customer requirements | |

| Heat Treatment | Annealed, Normalized, Quenched and Tempered, etc. | |

| Pressure Rating | e.g., 3000 psi, 6000 psi, or higher | |

| Temperature Rating | e.g., Up to 600°C (1112°F) or higher | |

| Surface Finish | Smooth, Pickled and Passivated, Polished, etc. | |

| Grade | ||

| Stainless Steel | 200 Series - 201, 202, 205.

300 Series 301, 302, 303, 304, 304L, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316TI, 317, 317L, 321, 347. 400 Series 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414,416, 416Se, 420,420F, 422, 431, 440A, 440B, 440C. 500 Series - 501, 502. 600 Series - 630 (17-4 PH). |

|

| Hastelloy | C22, C276, X, B-2. | |

| Monel | 400, K500. | |

| Nickel Alloy | Nickel 200 Nickel 201, Alloy 20, Alloy 286, Alloy 218 (Nitronic 60), Nitronic 50 (XM-19). | |

| Cupro Nickel | Cu 90-10 (C70600,CW352H), Cu 70-30 (C71500, CW354H). | |

| Inconel | 601, 625, 660A, 718, X-750, 825, 925, 608. | |

| Duplex / Super Duplex | D S31803, D S32205, SD S32750, SD S32760, SD S32950. | |

| Nichrome Alloy | CrNi 20/80. | |

| Copper | ASTM B1, ASTM B2, ASTM B3, ASTM B152, ASTM B124, ASTM B133. | |

| Brass | Alloy 260, Alloy 272, Alloy 330, Alloy 353, Alloy 360, Alloy C48200 - C48500, Alloy 464. | |

| Bronze | Alloy 954, Alloy 933. | |

| Mild Steel | Sae 4118, Sae 4120, Sae 4120, Sae 4130, Sae 4135, Sae 4137, Sae 4140, Sae 4142, Sae 4145, Sae 4147, Sae 4150, Sae 4161, Sae 8620. | |

Want to Understand Better Regarding this Product?

Contact us now for quick help.

What is the Composition of Boiler Tube?

Some of the most frequently used steels for boiler tubes include low-alloy steels containing alloying elements such as chromium, nickel, molybdenum, and vanadium, 9–12% chromium steels, austenitic stainless steels, austenitic heat-resisting steels, and nickel-base heat-resisting alloys. We are also a leading boiler tube Exporter in UAE.

Boiler tubes are typically made from alloyed steel with specific compositions to withstand high temperatures and pressures in steam boilers. Common materials include carbon steel, alloy steel, and stainless steel, with various alloying elements such as chromium, molybdenum, and nickel to enhance corrosion resistance, strength, and heat resistance. The composition is carefully chosen to ensure the tubes can withstand the harsh conditions of boiler environments, providing durability and reliability in power generation applications.

Leading Boiler Tube Manufacturer in Middle East - Piping Projects Middle East

Piping Projects Middle East is a well-known Boiler Tube Supplier in Middle East. We supply Boiler Tube to many cities and regions, including Abu Dhabi, Dubai, Sharjah, Ajman, Umm Al Quwain, and Fujairah. We are trusted supplier in the UAE and other countries nearby. Our Boiler Tube are excellent, and we are the preferred option for businesses and industries seeking high-quality piping solutions in the Middle East. We stand for on-time deliveries as we are the top Boiler Tube Manufacturers in Middle East.

Why are Piping Projects Middle East the Best Boiler Tube Suppliers in Middle East?

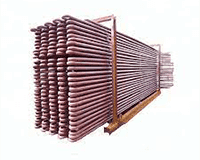

Stainless steel tubes heat liquids and manufacturer steam in different processes. They are very durable and can handle high pressure and heat levels, making them ideal for stainless steel boilers. The liquid is heated by flowing through these tubes. The tubes can be made by soldering or as one continuous piece. They are created by heating steel preforms and shaping them using a metal mould to manufacture seamless stainless steel boiler tubes. We are also a leading Boiler Tube Manufacturer in UAE.

Piping Projects Middle East is a leading Boiler Tube Supplier in Middle East. Our products come in different sizes to serve other uses and needs.

Want to Understand Better Regarding this Product?

Contact us now for quick help.

What is ASTM A178 Boiler Tube?

The ASTM A178 standard includes ERW tubes with a thin wall. These tubes are used in boiler tubing, boiler ventilation systems, superheater vents, and safety terminals. The ASTM A178 Boiler Tube is made of carbon steel and carbon-manganese alloy steel. The manufacturing process involves heat treatment and welding after cooling. We are also a top Boiler Tube Manufacturer in Middle East other countries worldwide.

The ASME SA178 Tubing comes in various sizes and wall thicknesses, ranging from 0.035 to 0.320 inches (0.9 to 9.1 millimetres). Tubes of different sizes are also allowed if they meet all the other specifications. for example, ASME SA178 Carbon Steel Tubes with an internal diameter and thickness less than 1/8 inches [3.2 mm] or 0.015 inches [0.4 mm] are considered to have specific mechanical characteristics.

What is the Difference Between Boiler Tube and Pipe?

Boiler tubes and pipes serve distinct purposes in industrial applications, particularly heat exchange systems. Boiler tubes are designed to withstand high temperatures and pressure conditions within boilers, where water is converted into steam. These tubes are often made of materials with superior heat-resistant properties, ensuring efficient heat transfer and structural integrity under demanding operating conditions. We are Top Boiler tubes Supplier in UAE.

On the other hand, pipes transport various fluids, including water, steam, or gases. While boiler tubes are a type of pipe, the term "boiler tube" is typically reserved for tubes engineered explicitly for boilers due to their specialised requirements, such as resistance to extreme temperatures and pressures. In summary, while both serve as conduits, boiler tubes are a specialised subset designed for the unique challenges of boiler systems.

Boiler Tube

Specification Highlights

Trusted

Supplier

Genuine

Product

Easy

purchase

Where are Boiler Tubes Used?

Boiler tubes find widespread application in various industries where steam generation or heat exchange is a critical process. They are extensively used in power plants, where boilers are crucial in converting water into steam to generate electricity. Additionally, boiler tubes are employed in industrial facilities like refineries and chemical plants, where high-temperature and high-pressure conditions are prevalent for efficient processing. These tubes are also integral components in heating systems for buildings and institutions, ensuring the reliable delivery of heat for space heating or water heating purposes. Overall, boiler tubes are essential in diverse settings where the controlled generation and transfer of steam or heat are fundamental requirements.

| Material Type | ASTM/ASME (USA) | EN (Europe) | DIN (Germany) | BS (UK) | JIS (Japan) | ISO (International) |

|---|---|---|---|---|---|---|

| Carbon Steel | A36 | S235JR | ST37-2 | 40A/B | SS400 | ISO 630-2 S235 |

| 304/304L | 1.4301/1.4307 | X5CrNi18-10 | 304S15 | SUS304 | ISO 15510 X5CrNi18-10 | |

| 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2 | 316S31 | SUS316 | ISO 15510 X5CrNiMo17-12-2 | |

| Aluminium | 6061 | EN AW-6061 | AlMg1SiCu | H20 | AA6061 | ISO 6361 6061 |

| Copper | C11000 | Cu-ETP | E-Cu58 | C101 | C1100 | ISO 13388 Cu-ETP |

| Length | Size |

|---|---|

| 16' 6" | 2.5" 0.105 SA178A |

| 18" 6" | 2.5" x 0.105" SA178A |

| 18' 6" | 2" 0.105" SA178A |

| 16' 6" | 2" 0.105" SA178A |

| 22' 6" | 2" 0.105" SA178A |

| 20' 6" | 2" 0.105 SA178A |

| 22' 6" | 2.5" X 0.105" SA178A |

| 20' 6" | 2.5" X 0.105 SA178A |

| 26' 6" | 2.5" X 0.105" SA178A |

| 24 6" | 2.5" 0.105" SA178A |

| 40 6" | 2.5" 0.105" SA178A |

| 28' 6" | 2.5" 0.105" SA178A |

| 20' O" | 2.5" x 0.120 SA178A |

| 26' 6" | 2" X 0.105" SA178A |

| 24' 6" | 2" <0.105" SA178A |

| 28' 6" | 2" 0.105" SA178A |

| 32' 6" | 2" x 0.105" SA178A |

| 40' 6" | 15" x 0.120 SA178A |

| 40' 6" | 1.5" "x0.105" SA178A |

| 40' 6" | 1.5" x 0.150 SA178A |

| 40' 6" | 15" x 0.135 SA178A |

| 40' 6" | 1.75" 0.135 SA178A |

| 40' 6" | 15" x 0.180" SA178A |

| 40' 6" | 175° X 0.180" SA178A |

| 40' 6" | 1.75" x 0.150" SA178A |

| 40' 6" | 2" X 0.120" SA178A |

| 40' 6" | 2" 0.150 SA178A |

| 40 6" | 2" X 0.135 SA178A |

| 40' 6" | 2" X 0.165 SA178A |

| 40 6" | 2" 0.203 SA178A |

| 40' 6" | 2" x 0.180" SA178A |

| 40' 6" | 2" X 0.220 SA178A |

| 40' 6" | 2.5" 0.120" SA178A |

Want to Understand Better Regarding this Product?

Contact us now for quick help.

Is SS Seamless Boiler Tubes Expensive?

Most stainless steel boiler piping is either seamless or welded. Seamless piping is better because it is made from a single piece of metal. However, it is more expensive to manufacture because of its unique process. This is because it contains molybdenum, which manufactures it high-quality. on the other hand, welded piping is generally cheaper because it has a more detailed manufacturing process.

Application & Uses of Boiler Tube:

Piping Projects Middle East is a leading Boiler Tube Manufacturer in UAE. We proudly supply high-quality Boiler Tube to major Middle East Countries. We have dominated the market as the Middle East’s leading Boiler Tube Exporter for a long time.

| Countries We Supply | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Saudi Arabia | Israel | Iran | Kuwait | Iraq | |||||

| Oman | Palestine | Egypt | Lebanon | Turkey | |||||

Boiler Tube Manufacturer & Supplier

Boiler Tube Manufacturer in Middle East

Boiler Tube Supplier in Middle East